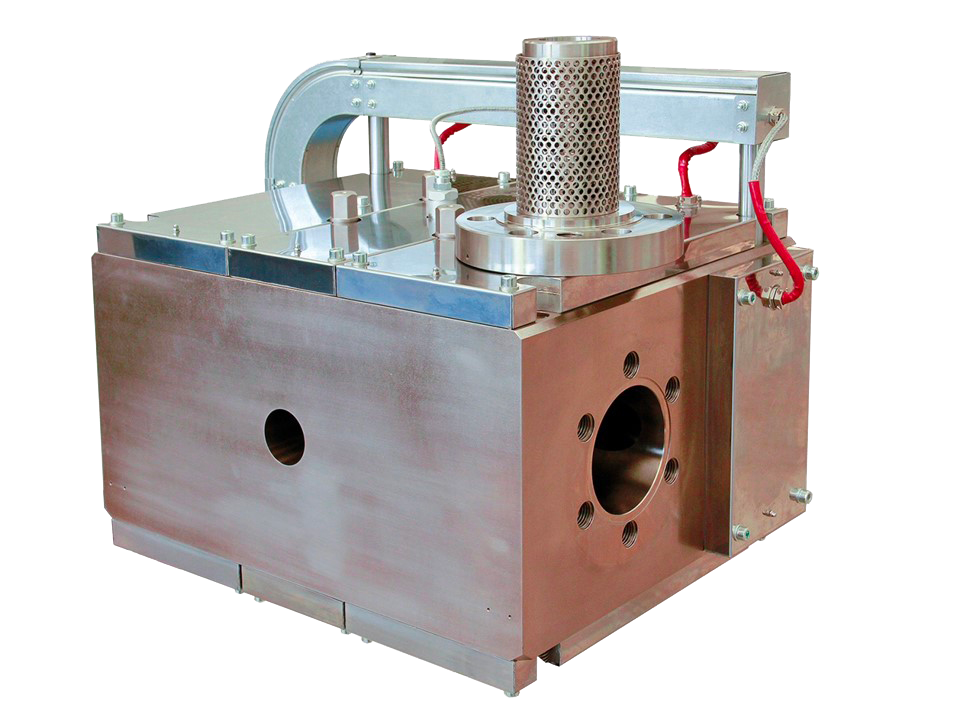

continuous manual screen changer

It is an exclusive patent. The continuous manual screen changer incorporates two parallel filter cartridges that are automatically cleaned one by one without being removed from the equipment., an exclusive patent, without being removed from the equipment.

While one cartridge is in cleaning mode, the melt flows continuously through the second filter cartridge. So the extrusion line is never stopped!

ADVANTAGES

- economical and reliable

- no hydraulic or pneumatic systems involved

- no control panel required

- maintenance reduced to a minimum

- strong and durable

- self-cleaning function, low cost machine operation, the chipest available in the market

- operating pressure values up to +500bar

In addition to being economical, the continuous manual screen changer is a highly durable investment for you low contamination materials:

SELF-CLEANING:

protected by the exclusive patent, the filter cartridges are cleaned without being removed from the block.

CONTINUE:

the filter cartridges can be cleaned and replaced without interrupting production.

ECONOMICAL:

The continuous manual screen changer does not require any expensive control panels or hydraulic power packs. Maintenance and spare parts are reduced to a minimum.

THE CHEAPEST SCREEN CHANGE FOR UNINTERROTABLE EXTRUSION SYSTEMS

It is made with a steel body for low maintenance and a trouble free life cycle.

| SCHEDA TECNICA | DATI TECNICI |

|---|---|

| Elaborazione: | Flusso continuo - autopulente |

| Area di filtraggio: | Fino a 1010 cm² (156 in²) |

| Stato del materiale: | Molto adatto per materiali a bassa contaminazione |

| Capacità oraria: | Fino a 1.500 kg / h (3.300 libbre) |

| Prodotti lavorati: | PE, PP, ABS, PET, PA, PS, ecc. |

| Applicazioni: | Film, fogli, filamenti mono, tubi, tubi e altro |

| Consumo energetico massimo: | 37 kWh |